CREDENTIAL

- ISO 9001: 2015 Certified

- Approved by Indian Register of Shipping

- Approved by DNVGL

- Approved by Bureau Veritas

- Approved by American Bureau of Shipping

- Approved by Lloyds Register of Shipping

- Approved by Class NK

- Registered with NSIC & MSME

- Qualified Team of Professional Divers

- Divers are Medically Certified & Insured

OUR SERVICES

Diving/Underwater

Ship Services

Port/Wharf/Piles, Fenders and Its Underwater Structures Maintenance

Buoy And Navigational

Aids Maintenance

Offshore Diving

Projects

Hydraulic

Equipment’s

Hyperbaric Intervention

Support Services

DIVING/UNDERWATER SHIP SERVICES

- Underwater Live CCTV Videography of Ships for Classification Purpose, Rudder, Pintle Clearance and Propeller shaft Wear Down Clearance

- Vessel/Ship Sea Chest and Overboard Value Blanking and Unblanking

- Underwater cold Repair for Hull Cracks, Holes and Dents Etc.

- Underwater Thickness Gauging Measurement (UW UTG/NDT)

- Removal of Fishing Net/ Ropes/ Tyre Fender from the Propellers

- Underwater Blanking Using Steel Mat

- Underwater Welding and Cutting

- Hydraulic Hull Cleaning Services and Propeller Polishing

- Removal of Fishing Net/ Ropes/Tyre Fender from the Propellers

PORT/WHARF/PILES, FENDERS AND ITS UNDERWATER STRUCTURES MAINTENANCE

- Wharf, Pile Inspection by NDT & Rejuvenation of damaged wharf, piles by “Pressure Grouting

- Underwater Inspection & Cleaning Works-Structures

- Underwater Core Drilling and Pile Cutting at Sea Bed Level

- Bathymetry / Depth measurement Survey

- Dredging /Abreast Wharf Area

- Dredging, Wharf Maintenance and Structural Integrity Analysis (UPV, CP Testing)

BUOY AND NAVIGTAIONAL AIDS MAINTENANCE

- Annual Maintenance (AMC) of Channel Buoys, Marker Buoys & Fairway Buoys

- Retrieval, Development and Maintenance of Solar Lanterns on Navigational Buoys

- Leading, Breakwater & Jetty Light Maintenance

- Fender Maintenance, Removal and Refixing

- Wave Powered Navigational Buoy (WPNB)- NIOT Authorized Manufacturer under “Make in India

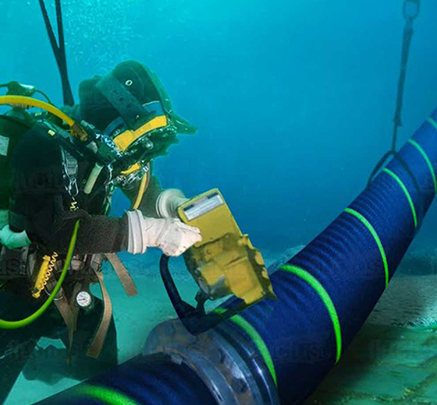

OFFSHORE DIVING PROJECTS

- Intake and Outfall Laying for Thermal Power Plants and De-Salination Plants.

- Underwater Repair and Maintenance of Pipelines

- Geo Textile Wrapping for Underwater Pipelines

- Fixing of Pipeline into Exact Trench in Underwater

- Underwater Cable Laying and Burying for 200m from Shore 1 Meter below the Sea Bed

- Underwater Inspection, Maintenance & Repairs of Offshore Structures

- SPM (Single Point Mooring) - Maintenance and Repair

- Diving Work at Atomic Power Plants

- Underwater PLEM Inspection for Chemical Plants

- Design, Drawings and Bathymetry Survey - We have tie-up with Premier Institutions at Chennai - We will Coordinate and ensure a workable, economical & reliable design for the project

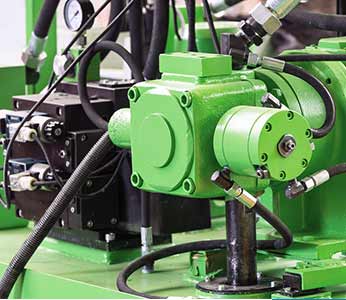

HYDRAULIC EQUIPMENTS

- Ship Hydraulic Equipment and Cranes

- Industrial Hydraulic Equipment’s

- Hydra Crane System

- Hydraulic Equipment Design Development and Fabrication for Special Purpose

- Hydraulic Pumps and Motors

- All Hydraulic Equipment Refurbishment and Sales

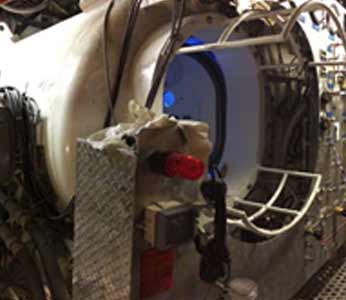

HYPERBARIC INTERVENTION SUPPORT SERVICES

- Compressed Air Work EPB-TBM

- TBM Air Lock and Support Personnel

- Hyperbaric Intervention Equipment’s Maintenance

- Medical Locks -DDC Supply and Maintenance

- CAW Worker and Training Awareness

- Hyperbaric Workers and Mechanics

- Compression and Decompression for CAW Workers

ACHIEVEMENTS

- Sinking, Live Tracking and Positioning of Intake / Outfall HDPE Pipe Line of 1600 /750mm DIA and 1050 /1200 Meters Length for Metro Water – VA Tech Wabag, 100 MLD Desalination Plant, at Nemili, Chennai.

- Sea Water Intake Well – Diffuser Installation - For Coastal Energen Tuticorin

- Underwater Cable Laying and Burying For 200m From Shore 1 Meter Below the Sea Bed - TYCO – VSNL Underwater Fiber Optic Cable Laying

- Underwater Cable Laying and Burying For 200m From Shore 1 Meter Below the Sea Bed - RELIANCE JIO - MCC Underwater Fiber Optic Cable Laying

- Re-Positioning of Channel Buoys for Vessel Movements at Channel After the Vardha Cyclone Hit and Resumed the Port Operations Within 24hrs.

- Permanent Insert on Ship’s Hull Using “Cofferdam” Technology Without Dry Docking.

- Using “Diamond Chain Sawing Technology” A Damaged Pile Under The Wharf of 1300mm Diameter with Steel Liner Of 10mm Thick, Around 7 Meter Length of Weight 22mt, At A Depth Of 12 Meter Was Sliced at Sea Bed Level and Removed As A Single Piece.

- Retrieval of Ships Anchor With 300 Meters of Chain and Re-Fixing Back to The Ship Without the Assistance of External Crane, After Tsunami.